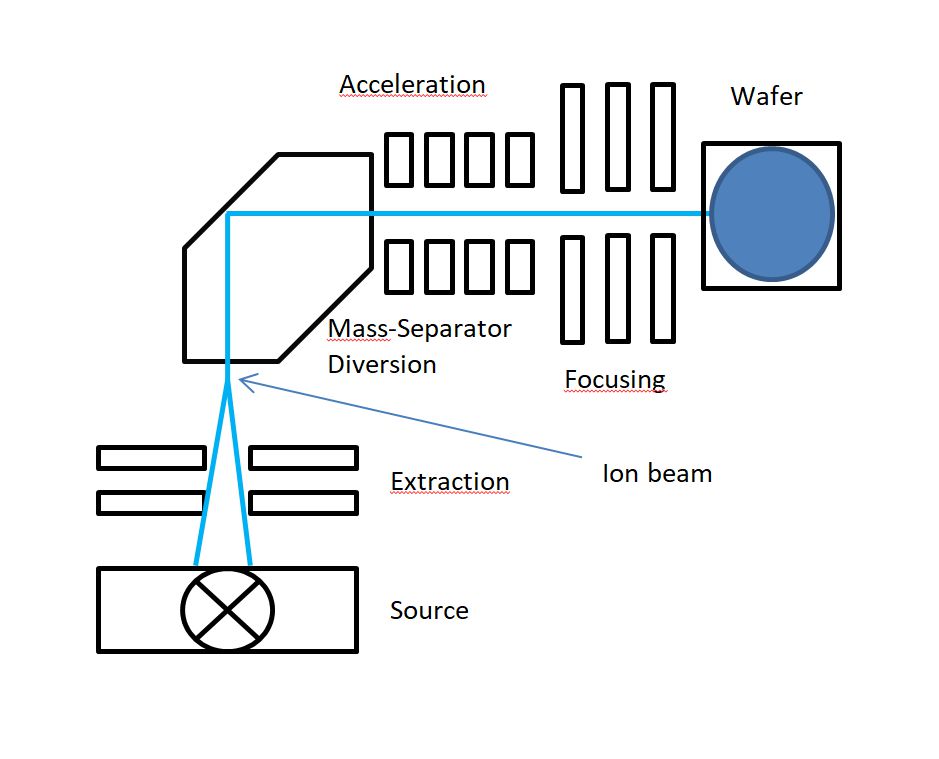

Ion implatation is a vacuum process in the semiconductor industry to dope wafers with ions, that change the electrical properties of the wafer material, e. g. the conductivity. The process is divided in the following steps: Creation of ions in an ion source, extraction and mass separation of ions for the selective implantation, diverion of the beam, acceleration and focusing of the ion beam to the wafer. This area of an ion implanter is called beam line.

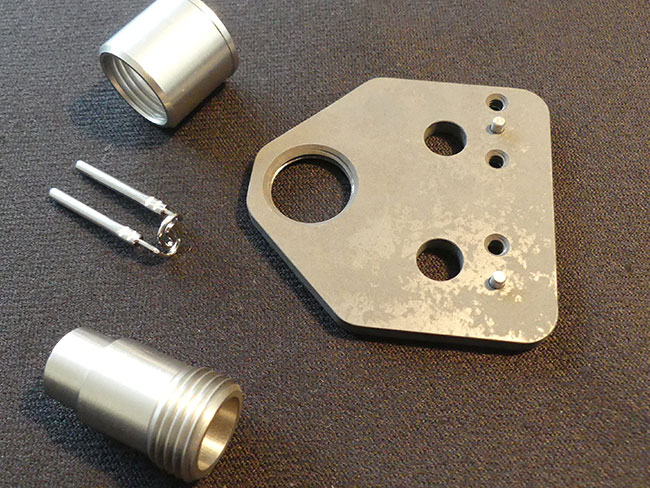

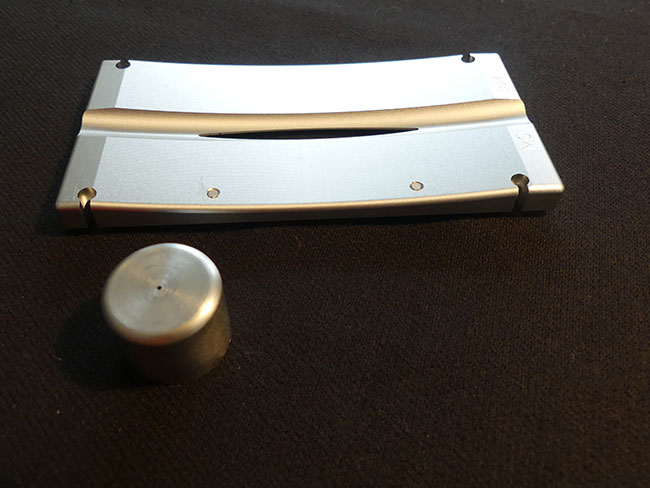

The high performance materials used for the parts in the beam line are Tungsten, Molybdenum, Tantal and Graphite. In addition isolators of high pure ceramics, e. g. BN are used.

CE-MAT provides high quality consumables and replacement components for the beamline in Ion Implanters of AMAT, Varian and Axelis. Equipment upgrades and modifications of parts according customers‘ requirements for process improvements are an additional service.

Schematic of the ion beam in an ion implanter.