The conventional materials used in furnace processes are either quartz glass or silicon carbide.

While quartz glass is used at moderate temperatures up to approx. 950 ° C, silicon carbide is used almost exclusively at higher temperatures.

However, both materials have a material specific disadvantage. Due to the difference of thermal expansion coefficients between the silicon wafer and the wafer holder and due to the direct contact between both, some serious defects occur on the wafer.

Examples are backside scratches and particles, dislocations and deformations.

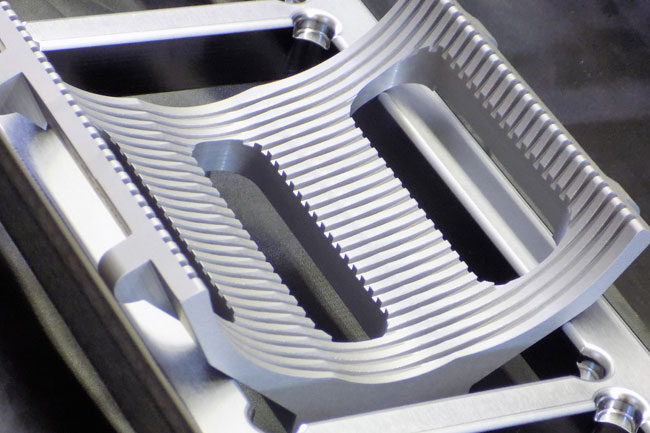

The use of silicon as carrier material reduces this negative influence significantly.

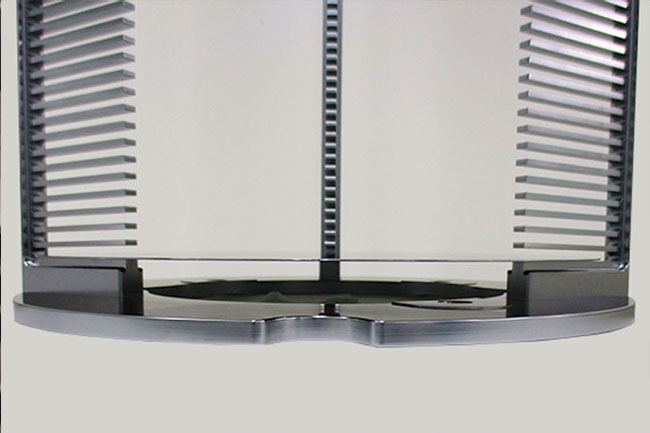

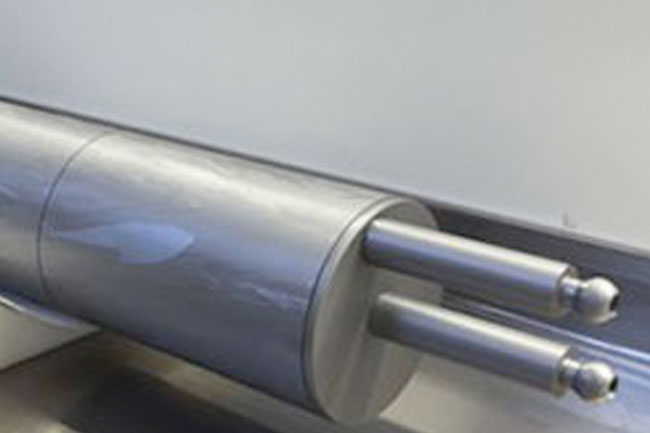

CE-MAT offers boats for vertical and horizontal furnace processes, specially designed boats with removable wafer holders, as well as silicon process tubes.