Rework at CE-MAT

Ever increasing challenges of the semiconductor industry in terms of process performance demand strong requirements for materials and parts in high precision. Aggressive process conditions lead to deterioration of the component properties due to chemical or physical corrosion, or the components become unusable due to mechanical damage.

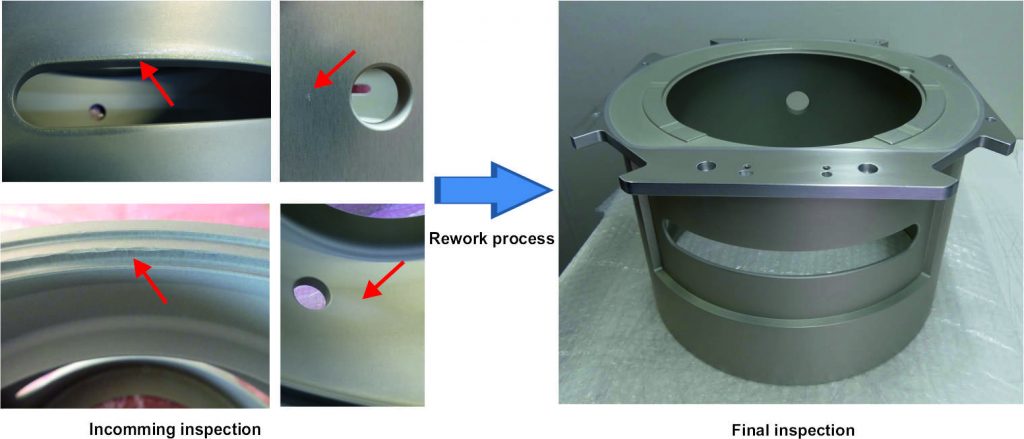

CE-MAT provides mechanical and / or chemical repair of process worn components which don‘t longer meet the demanded parameters. Through rework process ( reanodisation according MIL-A-8625 ) the components characteristics are returned to those very similar of new parts and have once again a further comparable lifetime or better. Most parts are reworkable!

The rework at CE-MAT is done according the following process-flow:

- Incomming inspection for all parts

- Component-specific preparation for the rework

- Stripping of worn coating

- Mechanical surface treatment

- Coating according to individual coating instructions

- Finishing

- Final inspection (including coating thickness, sealing value, roughness, breakdown voltage)

- Cleaning / cleanroom packaging

CE-MAT provides rework of anodized part as a new service. The parts damaged by the process and handling are refurbished to have a lifetime comparable to new parts. The anodisation in semiconductor grade offered by CE-MAT is international approved and qualified by many end users and by OEMs. Multiple Rework could be done for most parts, as only a new coating has to be applied to the high-priced components. Rework holds a considerable cost-saving potential.